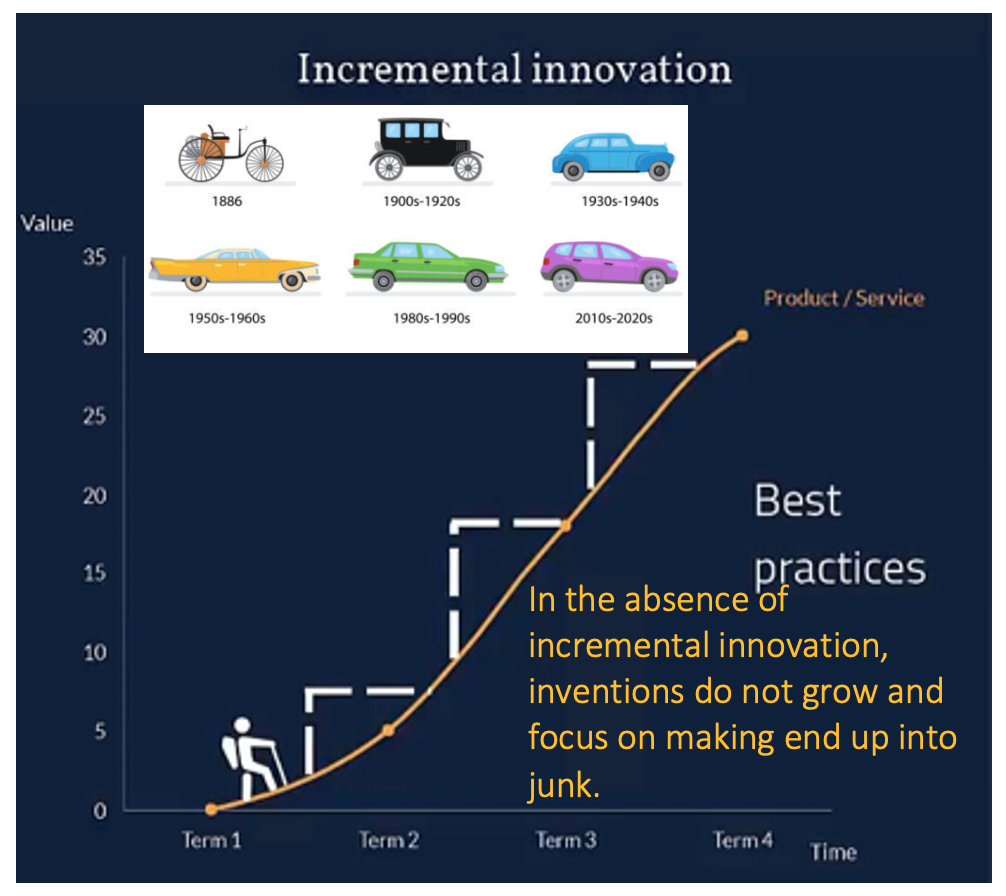

Innovation is a synonym to Eureka with a big spark in a light bulb. But the car evolution offers us a different lesson. Unlike a big bang, Carl Benz’s automobile has been progressively unfolding its latent potential. Incremental innovation has been the underlying force of car evolution, similar to the progression of many other industrial products. Over 130 years, there has been no Eureka; cars use the same gasoline engine to power four wheels. But without Eureka, why have German automakers succeeded in increasing the sale from 900 cars in 1901 to more than 6 million a year by 2020? Despite the absence of technological breakthroughs, incremental innovation has been shaping the car evolution and its competitive race. Hence, by leveraging it, late entrant Japan has become a global leader. But, by keep making the same Ambassador car for 60 years, India discarded it as junk.

Concept vehicles like Toyota FV2 or self-driving cars give the impression that the automobile industry is poised to experience Disruptive innovation. But over the last 130 long years, the basic principle of the automobile has not been changed. Like Model T Ford, the first mass-produced vehicle, we still use steering wheels, shift gear change, and an internal combustion engine that powers some kind of transmission to the wheels. Apparently, from the conversion of the vertical motion of the cylinders to the rotating wheel motion and from the tires to the suspension, there has been no major change. They are simply developments of existing principles and technology dating back to the industry’s beginnings. But the demand for the automobile has been steadily increasing. In the absence of any technology breakthroughs, which has been influencing competition and diffusion?

Incremental innovation is the driver of car evolution

The car we use today is far different than the gasoline engine-powered tricycle which Carl Benz invented in 1885. Instead of giving a push to start the engine, we press a button, often from a distance. There have been many such advancements. Over the last 130 years, many improvements have shown up, leading to car evolution. As opposed to breakthroughs causing a revolution, incremental innovation has been the driver of car evolution. Consequentially, the perceived value for money has been increasing. Hence, the diffusion of the car has been steadily expanding, making it the single largest industry.

On the other hand, incremental innovation’s competitive race has bankrupted many initial car makers. But, due to consistently superior incremental performance, Japanese automakers have become global leaders despite being late entrants. This incremental innovation journey has been expanding the technology base of cars, making them increasingly electronic gadgets.

Starting with Toyota’s principle kaizen, a constant and continuous improvement, to use robotics in production, the automobile industry is progressing by an endless loop of iteration of incremental innovation. There has been a race among automobile makers to outperform competitors in incremental innovations. This incremental innovation has remained the core competence over the last 100 years for acquiring the capability of offering a better quality car at less cost. Upon failing in this incremental innovation race, many companies, starting from India’s Ambassador to many carmakers of Eastern Europe and the former Soviet Union, could not sustain. It’s not due to the fact that they were not producing cars similar to the ones made by Toyota or Honda; rather, they were suffering from very slow progress in incremental innovations. Some of the strategic thinking and areas of incremental innovations in driving the automobile race are as follows.

Keep delegating roles from mechanical to electromechanical and electronic devices

One of the strategic focuses has been on reducing the role of mechanical devices. Over the last 100 years, many of the roles of mechanical devices, starting from oil flow control to ignition, have migrated to electromechanical and electronic devices. Today an average new automobile includes more than 40 electronic controllers and five miles of wiring in connecting them. In the race of improving automobiles, Electronics have been important in improving two major aspects of vehicle performance. The first one is about refining the powertrain to reduce emissions and improve fuel consumption. And the other one is refining the chassis, exterior, and interior to improve vehicle safety and comfort. Progress in such role delegation increases fuel efficiency, reduces emissions, and increases comfort.

As a result, there have been visible benefits. Some of them are lower cost for fuel, higher comfort, and less harm to the environment due to decreasing emission. The innovation of hybrid cars has exploited this strategy to a new height. The role of providing energy has been partially shifted from mechanical engines to batteries and motors, significantly increasing fuel efficiency. Both economics and regulation made this incremental innovation strategy a key success criterion in the competitive race in the automobile industry.

Car evolution benefiting from delegating roles from tangible hardware devices to software

A typical automobile today has more than 10 million lines of software code. Cars increasingly rely on software to manage everything from advanced drivetrains to elaborate infotainment systems. As stated by Wired magazine, as high as 90 percent of automobile innovations are from software advancement. The implications of the delegation of all the functionalities you might have in electronics or mechanical (systems) to the software are going to be significant in both quality and cost. Unlike electronics or mechanical devices, sophisticated algorithms could be integrated into the software to get many jobs, starting from engine to internal climate control, done better at less cost.

Moreover, reliability does not deteriorate with aging once we succeed to develop error-free software. On top of it, the cost of software replication is zero. As a result, carmakers are deriving significant competitive advantage, particularly in Economies of Scale and scope, out of the increasing role of software. Hence, automakers are moving further in exploiting the benefit from software by integrating smartphones with cars. They have been after apps for allowing drivers to do everything, such as locking their doors and programing exactly when their electric car starts drawing power from the grid.

Delegating roles from human to machine in making driving easier and safer

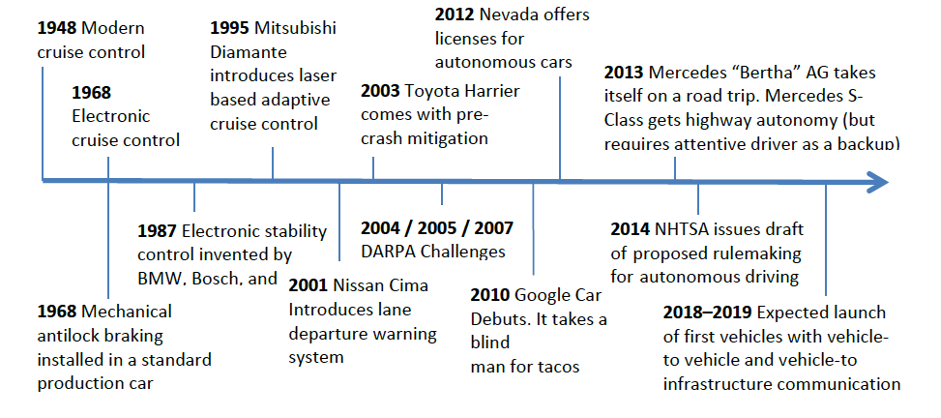

Although self-driving cars are making headline news, automobile makers have been making incremental progress in delegating the roles of driving to automobiles themselves. Such role delegation has been making driving increasingly easier and safer, sometimes more economical. Often, we receive advice from the car navigation system to select a route and change it while driving to avoid congestion. Another example is the lane detection system, advising us to take measures while drifting from a designated lane. Some of the major progress, along with likely ones, in delegating driving roles to automobiles themselves are shown below:

Delegate roles of making automobiles from human to machines

In producing Model T Ford, most car parts were made and assembled together by human hands. Eventually, the body was also pained by hand. Since then, over the last 100 years, there has been a race in transferring roles from humans to machines or robots in making cars. Such role delegation to the machine has increased the quality and reduced the cost at each iteration loop. Robot paints cars more uniformly than human did in the past. And the cost of painting done by the robot is also less. The use of robotics in making cars dates back to 1961, performing spot welding jobs in General Motors’ facilities. The success of welding job delegation to robots encouraged the development of Stanford Arm, with six degrees of freedom in 1969. In 1974, MIT came up with a more versatile new arm with embedded pressure-sensitive sensors and a microprocessor.

These early use of robots in making cars for better quality at less cost opened a new race of incremental innovation, resulting in a years-long robot boom with 30% year-on-year growth. The competition of using increasing roles of robots has reached almost 90 percent automation in BMW’s car-making plant in South Carolina. Instead of revolution, the growth of using robots has been incremental. As reported by the media, in 1994, robots made up only 2 percent of BMW’s assembly line workforce. Over the years, increasing roles have been delegated to robots to perform diverse tasks, from welding to assembling to painting.

Wining incremental innovation race: the underlying force of car evolution

In addition to those four major areas, incremental improvements are taking place in many other areas. It spans from increasing the reuse of the same parts in multiple models, updating designs to reduce the chance of making mistakes to making components multifunctional black boxes. Incremental innovation has been the driver of the competition in offering better quality automobiles at less cost. It’s not the access to Breakthrough technologies driving the revolution. Instead, the ability to benefit from incremental performance improvement by leveraging emerging technologies has been determining the success in the competition space of the automobile industry.

Often those technologies did not come into existence for the purpose of the automobile industry. For example, the development of electronics, microprocessors, and software took place quite outside the automobile industry. But the growth of those technologies opened the opportunity to the automobile industry to benefit from incremental innovation. Such reality reinforces the necessity of technology monitoring and managing incremental innovation to benefit from relevant technology growth. Often such a significant role in incremental innovation does not have visibility from the outside. In the absence of meticulous attention to benefit from incremental innovation, even an early success does not sustain. Such an important role of incremental innovation also makes replication-based competition strategy quite ineffective and wasteful.

Technology and innovation management for driving and leveraging incremental innovation

In addition to core mechanical technologies, like gasoline engines, many technologies have been contributing to the incremental advancement of cars. Hence, there is a strong need for managing a technology portfolio. The lifecycle of pertinent technologies should be carefully monitored, and adequate organizational competence should be developed to leverage them. Furthermore, for sustaining innovation, the competition space demands consistent incremental advancement in releasing successive better versions. Hence, there should be a strong focus on systematic ideation and idea portfolio management. There should be a close synchronization between technology and product lifecycles and innovation strategy. Furthermore, in expanding the technology base, we need to address technology uncertainty issues. Often, emerging technologies offer both treasures and traps. Hence, there should be a focus on technology forecasting.

Lessons from car evolution

In retrospect, the big success in car innovation has been in evolution, as opposed to having a big bang out of Eureka. Often, this fact does not get due attention. Due to it, some companies or countries focus on making, as opposed to incrementally advancing them. Some of them also pay great attention to the invention, as if invention alone pushes up prosperity with a big bang. But a few intelligent firms and countries focus on incremental advancement of already available products. They meticulously focus on technology and product Lifecycle management to outperform the competition. Hence, without inventing or even being a late entrant, they succeed in creating a huge success out of incremental innovation.

Unfortunately, many others suffer from failures due to focus on import substitution through borrowing ideas or transferring technology and creating profit-making opportunities to keep making the same products. Hence, the industrial strategy should focus on evolution through incremental evolution, as opposed to just keep making. Furthermore, even the success of inventions demands evolution through incremental advancement. In retrospect, car evolution offers us a valuable lesson of creating a success out of incremental innovation.

...welcome to join us. We are on a mission to develop an enlightened community by sharing the insights of Wealth creation out of technology possibilities as reoccuring patters. If you like the article, you may encourage us by sharing it through social media to enlighten others.